| WOOLGATHERERS - FAN (ONDULE) REEDS | |||||

|

Weaving reeds usually consist of wires set at regular intervals to keep the threads spaces correctly for the developing cloth. |

CLICK HERE FOR A MOVIE SHOWING THE FAN REED IN ACTION Chrome will not work, IE Explorer needs Quicktime Viewer - video also on Woolgatherers Facebook Page - Woolgatherers Ltd., LLC |

|

| The FAN REED sets the wires at fanning angles. These are also known as ondule reeds, and are are taller than normal reeds. During weaving, the warp threads move gradually from a spaced position to a crammed position, and back again. The resulting cloth shows undulating effects along the warp direction, and is known as warp ondule. |  |

|

| Instructional 15 minute video and handout - $20 without reed purchase. | Reed designed and manufactured March 2007. 22" long, 15 epi center spacing. |

|

| Here is a detailed photo of the FAN REED, showing how the spacing and cramming of the warp threads is conducted. |  |

|

| THE WOOLGATHERERS offers FAN REEDS to weavers who desire something special to enhance their weaving palette. These are custom made reeds with a lead time of 4-8 weeks from time of order. | Detail of reed shown above. |

|

The fan reeds that we import are made of quality stainless steel with aluminum profiles and have 2 inch sections. The 5.5 inch height has 1 inch sections at the narrowest point and 3" at the widest. This angle is capable of giving a steep curve - and flatter ones are always possible.The center, where the dents are even, is 12 dents per inch.

|

PRICING - Includes DVD with 15 minute video and handout showing how to use the fan reed (Convergence Class documentation from 2010). |

|

| 16" - 12 dpi (50/10) on center | $420 | |

| 16" - 15 dpi (6010) on center | $475 | |

| 24" - 12 dpi (50/10) on center | $565 | |

| 24" - 15 dpi (60/10) on center | $595 | |

| Other sizes are available on request, but require a special quote. Over 22" in length costs double for shipping because of postal size restrictions. | ||

| CUSTOM REEDS/SPECIAL WISHES | ||

| FAN REEDS can be designed by the weaver. There are, naturally, technical limitations to the design process. | ||

| Alternating sections of fans and straight reed ARE possible. | Reed Height - between 5.5" and 6" | |

| The construction of the reed does not allow changeable density and removable sections. The reed wires are mounted with precision under tension so they remain in the configuration set up when they are manufactured. | Center spacing (denting in center of reed) between 10 and 20 epi | |

| Since we began offering these reeds, there are now "RAIL REEDS" available with small sections, each offering variable density. | Minimum length 16" | |

| For more detailed information, please go to the Rail Reed site. | Maximum length 48" | |

| The two concepts are not interchangeable, nor can they be used "mix and match". | Width of the fan and the resulting angle can be specified. Contact us to determine if your desired reed is feasible. | |

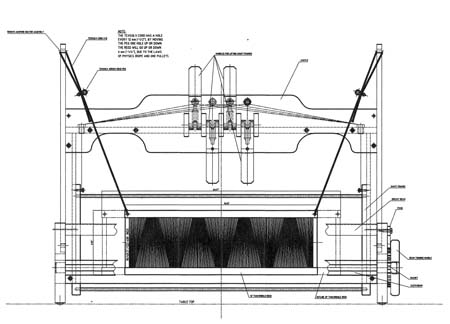

| MOUNTING THE FAN REED ON YOUR LOOM | ||

The fan reed must be able to move up and down in relation to the fell line in order to produce the undulations. There are several ways to do this. Since the fabrics usually produced in this manner are fine and delicate, a beater assembly is not necessary. Hans makes a small wooden handle that clamps onto the reed that replaces the usual wooden beater bar. The reed then hangs freely on two cords - which allows great flexibility in design. |

The simplest mounting method involves suspending the fan reed from two Texsolv 12mm buttonhole cords and moving the reed up and down using the holes in the cord and the arrow pegs. This works best with looms that have a high castle. Below is a sketch of how this works on an Ashford table loom - the cords are simply looped through the holes already present in the overhead beater. |

|

Wooden handle so you can use the fan reed without a beater ($18). |

|

|

| Designing and weaving with a fan reed emphasizes color, texture and yarn spacing. It is a perfect medium for optical illusion and unusual color combinations. Below are some photos of my first sample warp using the fan reed. the yarn used is 10/2 mercerized cotton in Tubular Spectrum colors from Lunatic Fringe - sett 24 epi. Navy blue was 20/2 doubled in warp and used as a single strand for weft in one of the pieces. |  |

|

| This sample was woven at the end of the warp. Plain weave. Whe lifting device was not used. The subtle undulations are the result of the fan reed striking the fell line at slightly different angles. Each advance of the warp grought onr of the "bumps". | ||

| Using the single 20/2, treadling was in a sequence using #1 of the twill and alternating tabby giving a warp stripe effect beyond the colors used. |  |

|

| Using the medium blue as weft, treadled with a broken twill. |

|

|

| Straight 4-shaft twill with light green weft. |  |

|

| Tabby with darket green weft. |  |

|

| Click on the small photos for more detail. | ||

| For additional examples of warp ondule fabric - click here | Contact us for more information and quotation. | |