I've been weaving pretty much since I started spinning , mostly because there was more yarn available than could be knit up comfortably.

The first loom was a rigid heddle - followed by the 8-shaft Finnish countermarche loom, 48" wide, pictured at below.

It is warped to make 45" wool fabric to be felted after weaving.

MY PRIMARY LOOM - A LILLQVIST FROM FINLAND - 8 shaft, 10 TREADLES, 48" WIDE, COUNTERMARCHE

p>

p>

NOW, A NEW DIMENSION IN WEAVING - WITHOUT NEGLECTING MY TRUSTY LILQVIST LOOM!

AS OF JANUARY 2009, THE LOOM HAS BEEN SUCCESSFULLY CONVERTED TO A 16-SHAFT COMPUTER ASSISTED DOBBY LOOM.

| The Lilqvist has been so satisfactory over the years that I treated myself to a Swedish vertical countermarche loom from Öxabäck - that way I have another loom with the same system of warping and weaving. The new, smaller loom wasintended for mid-sized warps of fine table linens. Lilla is such a delightful loom that she has now been transformed into a drawloom with 50 pattern shafts. |

|

The dobby unit is from Toika in Finland - designed for their countermarche looms, yet easily adaptible for many brands of traditional Scandinavian loom - or an old "barn loom".

The loom is still the same. Only the sticks and strings that made it a traditional countermarche loom have been removed. A simple box is mounted in the place of the countermarche beams and the 16 shafts hang freely from the electronic box.

A simple foot control selects the shafts, allowing for more complex treadling sequences. Frequent interruptions are also better handled - by simply lifting the foot off the pedal and putting it back down later.

This is definitely worth considering, both for increasing the complexity of what can be woven and allowing for physical impairments as the weaver ages.

|

| |

|

This is the first project. Warp 720 threads, Number 16 linen for linsey woolsey. The first half had been woven and cut off when we decided to convert the loom. I worked out some designs, rethreaded the loom with an 8-shaft point threading and tested some traditional Danish patterns from "Danske Bondevaevninger, bd. 1" .

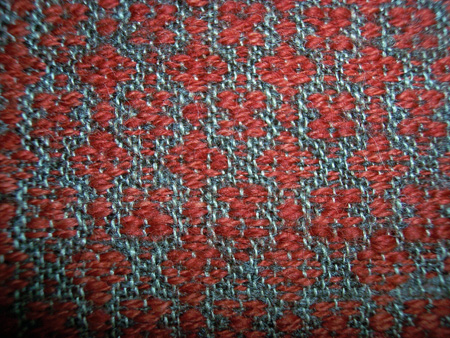

The fabric at right is a sweet little motif that would work up well as a small vest. |

|

|

|

|

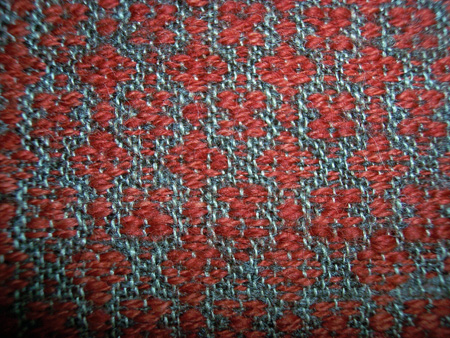

This fabric, made for a skirt where the fabric is then tipped 90 degrees letting the motifs run vertically, combines 4 different patterns. Each pattern requires its own tieup and treadling. Combining them with tabby between is not at all difficult when working with the dobby box. |

| |

|

|

MY 8-SHAFT VERTICAL COUNTERMARCHE - THE LILLA

An Öxabäck small footprint vertical countermarche loom - 8 Shaft/8 Treadle. The back beam can be folded to save a foot of space - which I truly need.

This loom was the easiest one I have ever set up - we found the instructions after the wood pieces were already assembled and we were beginning with the tie up. Precut Texsolv cords and colored twist ties made it foolproof. The treadle tie up was done without warp and gave a perfect shed as the first project was threaded and ready to weave. |

|

A view from behind the back beam - definitely a good addition and makes good use of the "muscle memory" learned from years of weaving on the larger Lilqvist loom.

|

|

In Sept. 2005, Lilla was transformed into a 50 pattern shaft drawloom and is now happily working in the shop. |

| |

|

|

GLIMAKRA AKTIV

A Glimakra 8-shaft Victoria table loom gave wonderful service, but was a bit slow, so I sold it and added a used Glimakra Aktiv 8-shaft countermarche. The Aktiv is a folding loom buils in A-frame. The weaving frame is much like an oversized Victoria. It weaves very nice fabrics. An unusual feature of the Aktiv is that there are 2 lams for every treadles, but these lams are both mounted at the same level. |

|

|

| |

|

|

CRANBROOK RUG LOOM

Just to keep life interesting, in April 2007 I set up a used Bexell Cranbrook rug loom - 45" wide 4-shaft. Always thought the Lilqvist made nice rugs - until the Cranbrook. Beating is one of those activities that ease the frustration of daily life.

|

|

|

| |

|

|

KIRCHER RIGID HEDDLE LOOM - 32" WIDE - FLOOR STAND, WARP FLANGES - HEDDLES CAME TO 15 DENT. MY "BASEMENT" LOOM FOR SPECIAL PROJECTS.

I also acquired a replacement rigid heddle loom along the way - the same model I started with from Walter Kircher in Germany who actually made warp flanges (mounted in photo) for this loom - it could also be modified into a 4-shaft loom by adding a special kit. |

|

This loom is rather versatile - I recently purchased the attachments that turn it into an upright tapestry loom. |

|

Warping a rigid heddle need not be difficult. I adapted Rowena Hart's warping method (the Ashford loom has tie on sticks and she does this ON the loom) to warp from a single (I doubled the warp so used 2 cones) package right into the heddle - put a stick on the dining table and later put that over the warp beam on the loom, cut the loops and put the warp ends around the little wooden pegs - found on several brands of rigid heddle. |

|

he warping blocks or clamps determine the length - there is no cross - the warp is in the slots of the heddle until it is wound evenly onto the warp beam - then every other thread is put into the holes. The book is reasonably priced and well worth the investment if you own such a loom. |

| |

In addition to the looms pictured here, I have several smaller ones - inkle, and tapestry

Warping is done on the big 4m Toika vertical warping mill. (One corner can be seen in the rigid heddle loom photo.)

|

p>

p>