WOOLGATHERERS

FLAX/LINEN PROCESSING TOOLS

| SPINNING | WEAVING | DYEING | LINEN - MY SPECIALTY | FLAXCAM | FLAX PROCESSING | FIBER REFERENCE - LIBRARY |

| |

WOOLGATHERERS FLAX/LINEN PROCESSING TOOLS |

||||||

|

FLAX/LINEN PROCESSING TOOLS |

FLAX PROCESSING TOOLS

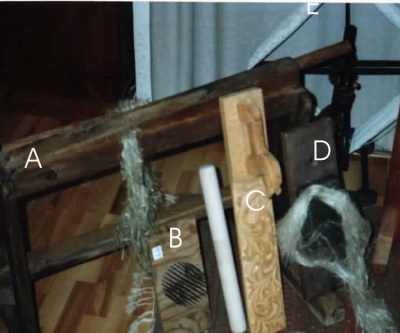

SPINNING WHEEL AND SCUTCHING BOARD SHOWN BELOW

|

Turning flax into linen thread and then into cloth requires not only time and back breaking labor, it requires a set of tools peculiar to the process. Pictured here is what is needed to transform the retted, dried flax straw into linen thread.

A.

The FLAX BREAK. This clumsy wooden device chops away at the straw. When the straw has been properly retted and dried (this step should not be done in humid weather without predrying the straw in a warm place) the chaff literally breaks away from the fiber. A sample of broken flax is hanging from the break. Of course, not ALL chaff is removed. The next step involves F - the scutching board and knife. There the hardwood knife beats more of the chaff away from the fibers.

B. and D.

These grizzly beds of nails are HACKLES. The broken and scutched flax is then drawn through these nails. B. is a medium hackle, made by my husband of sharpened nails put through plywood backing. D. is an antique fine hackle purchased on eBay. A sample of hackled flax is shown in the teeth of the fine hackle. In this step, there is quite a loss of fiber as the short and broken fibers are pulled out of the bundle of shining long flax. These shorter fibers are later combed and hackled again to produce the TOW linen - thread spun from the shorter, and mostly coarser fibers resulting as a sort of leftover of the pre-sinning process. The long, combed LINE fibers are bundled into a "strick" to await dressing the pinning wheel.

C.

This is a mangel board, used to press finished woven goods. It belongs to the set of tools needed to make linens for the household. My husband made this board at a carving class and the roller is actually a French rolling pin. (More about the mangel board is found under Care of Linens).

G.

Spinning flax into linen thread is done with a spinning wheel (or spindle). I prefer to work with a dressed distaff - H and J - to keep the fibers prepared for pulling down to spin. This arrangement is based on a conscious "tangling" of the fibers so that there is a continuous feed until the last dregs have been spun. The distaff is bound up with a handwoven linen Inkle band (J).

Linen is spun wet - that is the spinner places a container with water nearby and dips her fingers in the water frequently to help smooth the spun yarn.

A sample skein of handspun linen is pictured with other Handspun Yarns.

|

| ©2005 The Woolgatherers Ltd, LLC Last Updated 21-Aug-2008 |

Online Catalog • Imported Linen Fabric • Linen Yarn • Care of Linens • Mangling |